Facilities

Promac operates a modern, fully equipped machine shop. Our 18,000 feet of production space provides ample room for manufacture and assembly. Our comprehensive overhead crane system, mobile lift, and in floor heating system ensure a safe and efficient manufacturing environment.

TURNING DEPARTMENT

|

Manual

Qty = 1 Modern

X - 22" , Z - 80" , 4" thru bore with DRO Qty = 1 Modern

X - 18" , Z - 48" , 3.625" thru bore with DRO

CNC Lathe

Qty = 2 Okuma Turning Center Cadet 1420

X - 14" , Z - 25" , 3.25 thru bore Qty = 1 Nakamura Turning Center

X - 12" , Z - 22" , 3.125 thru bore Qty = 2 L470 Okuma Turning Centers with live tooling

X - 14" , Z - 48" , 4" thru bore Qty = 1 VIPER VT50 II Turning Center

X - 29" , Z - 72" , 9.25" thru bore Qty = 3 Haas SL40 Turning Centers with live tooling

X - 26" , Z - 40" , 7" thru bore Qty = 1 Haas SL40 Turning Center with live tooling

X - 26" , Z - 40" , 6" thru bore Qty = 1 Leadwell LTC-35 CXLY with live tooling & +/- 4" travel in Y

X - 14" , Z - 80" , 7.5" thru bore Qty = 1 Haas ST40 Turning Center with live tooling

X - 26" , Z - 70" , 7" thru bore Qty = 2 Haas ST35 Turning Center

X - 12.5" , Z - 26" , 3.5" thru bore |

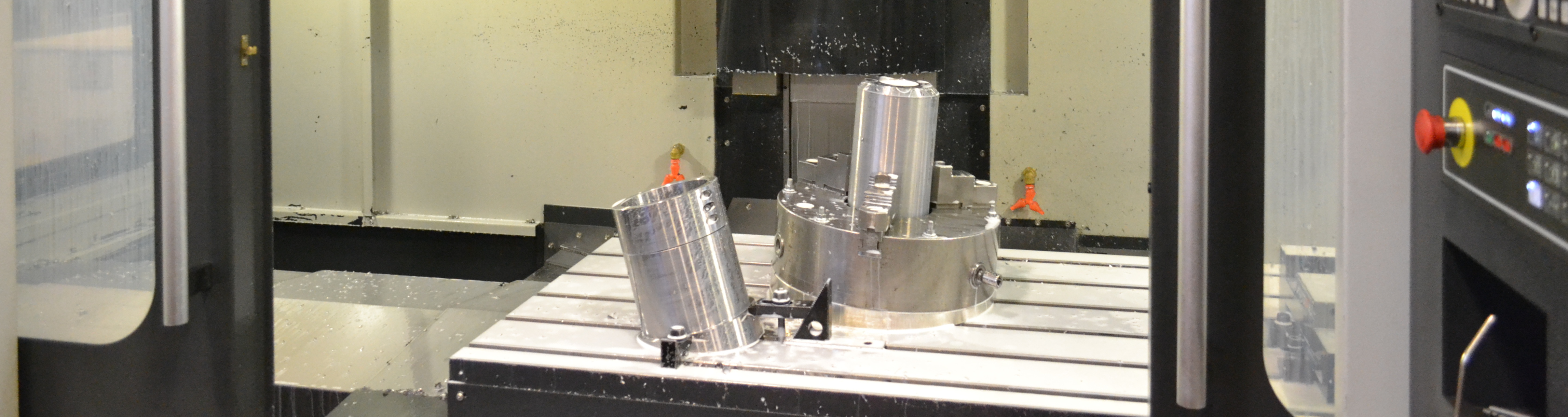

MILLING DEPARTMENT

|

Manual

CNC Mills

Qty = 2 Haas VF4 Milling Centers

X - 50" , Y - 16" , Z - 20" , 5 axis Qty = 1 Haas VF5 Milling Center

X - 60" , Y - 26" , Z - 25" , 5 axis Qty = 2 Haas VF6 Milling Centers

X - 60" , Y - 25" , Z - 30" , 5 axis Qty = 1 Leadwell V-60i Milling Center

X - 60" , Y - 30" , Z - 40" , 4 axis

|